|

|

|

|

|

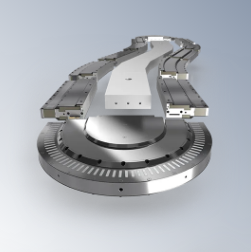

AT2xxx, ATH2xxx | XTS motor modules In the XTS motor modules, all active components are combined in a compact mounting space. |

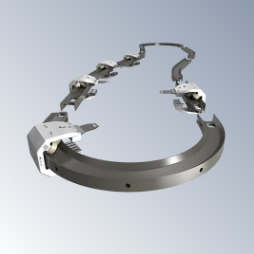

AT8x00, AT9xxx, ATH9xxx | XTS guide rails and movers The guide rails and movers form the passive components of the XTS for a linear motion along a track. |

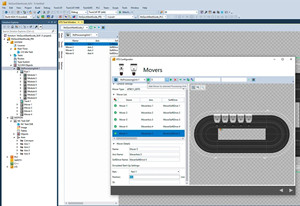

XTS software The TwinCAT 3 XTS extension enables simple configuration, simulation and operation. |

XTS starter kits The all-round package from system assembly to commissioning enables a quick and simple entry. |

The No Cable Technology (NCT) extension of the XTS system is the basis for a new leap in terms of machine flexibility. For the first time, a power supply and synchronous real-time data communication are available on the moving XTS movers, with which the individual XTS movers can be expanded into mobile handling and processing stations. In addition to the previous pure product transport, NCT enables additional process sequences directly on the mover itself.

XTS with NCT enables new solutions

NCT makes it possible to process and check the quality of products on the mover while the process is running. Sufficient power and fast communication with the TwinCAT control system enable easy connection of sensors and actuators. The data communication is real-time capable and can synchronize system-wide events with µs accuracy in connection with EtherCAT. This opens up new solution options for the user, especially in the areas of product handling, machining and measuring in parallel to product transport, as well as adapting production machines for rapidly changing production batches.